PROCESS COST ACCOUNTING

Comparing Job Order and Process Cost Accounting Systems

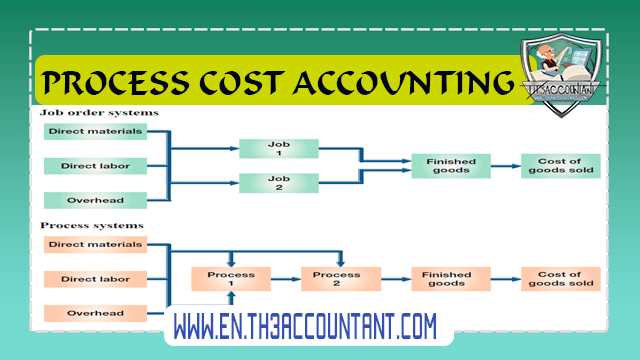

Both process and job order operations integrate materials, labor, and overhead in the process of creating items. They differ in terms of organization and management. A work order costing system focuses on the particular task or batch, whereas a cost accounting system focuses on the overall cost. It is a costing method for specific processes. Regardless of measuring emphasis, we are ultimately concerned with assessing the cost per unit of product (or service) as a result of whichever system.

The job order cost accounting system, in particular, assigns direct supplies, direct costs, and overhead to projects. The overall cost of the project is then divided by the number of units to determine the cost per unit for that job. The process cost accounting system allocates particular processes direct materials, direct labor, and overhead (or departments). The total costs associated with each process are then divided by the number of units that transit through that process to calculate the cost per equivalent unit . The differences between these two systems' approaches to materials, labor, and administrative expenses are underlined.

Direct and Indirect Costs

Process cost accounting systems, like work order operations, employ the notions of direct and indirect costs. A cost is direct if it can be traced back to the cost item; otherwise, it is indirect. Materials and labor that can be linked back to specific processes are assigned as direct expenses to those operations. Indirect expenses are materials and labor that cannot be traced back to a specific process and are attributed to overhead. In process cost accounting, some expenditures designated as overhead in a task order system may be classed as direct costs. Depreciation of a machine employed exclusively by one process, for example, is a direct expense of that operation.Accounting for Materials Costs

The arrival of materials at GenX's manufacturing is shown by arrow line 1. These resources Prifelone, flavorings, preservatives, and packaging are all included. They also contain supplies for the Office of production support GenX operates on a permanent inventory system and performs all purchases on the spot. The summary item for raw material receipts in April is as follows (dates in journal entries). Numbers 1 through 0 are excluded since they are summary entries, frequently reflecting two or more items. more transactions or occurrences| Credit | Debit | Description | N |

|---|---|---|---|

| 11,095 | Raw Materials Inventory | ||

| 11,095 | Accounts Payable | 1 | |

| Acquired materials on credit for factory use. |

| Credit | Debit | Description | N |

|---|---|---|---|

| 9,900 | Goods in Process Inventory | ||

| 9,900 | Raw Materials Inventory | 2 | |

| To assign costs of direct materials used in production |

| Credit | Debit | Description | N |

|---|---|---|---|

| 1,195 | Factory Overhead | ||

| 1,195 | Raw Materials Inventory | 3 | |

| To record indirect materials used in April |

Accounting for Labor Costs

shows GenX plant payroll expenses, as shown by arrow line 4. Labor charges of $8,920 are paid in cash and recorded in the Factory Payroll account.| Credit | Debit | Description | N |

|---|---|---|---|

| 8,920 | Factory Payroll | ||

| 8,920 | Cash | 4 | |

| to record factory wages for April |

This entry was generated by time reports from the production department and the production support office. (For clarity, we do not identify withholdings and supplementary payroll taxes for employees individually.) A production department's direct labor in a process operation comprises all labor employed entirely by that department. This is true even if the work is not directly applied to the product. If a process operation's manufacturing department, for example, has a full-time manager and a full-time maintenance worker, their wages are direct labor expenses of that process and not factory overhead.

In the production department, arrow line 5 shows GenX's utilization of direct labor. The following transaction moves the direct labor expenses for April from the Factory Payroll account to the Goods in Process Inventory account.| Credit | Debit | Description | N |

|---|---|---|---|

| 5,700 | Goods in Process Inventory | ||

| 5,700 | Factory Payroll | 5 | |

| to assign costs of direct labor used in production |

| Credit | Debit | Description | N |

|---|---|---|---|

| 3,220 | Factory Overhead | ||

| 3,220 | Factory Payroll | 6 | |

| To record indirect labor as overhead. |

Accounting for Factory Overhead

Arrow line 7 represents overhead expenditures other than indirect materials and indirect labor. Overhead costs include insuring production assets, renting the factory building, utilizing factory utilities, and depreciating equipment that is not directly tied to a certain activity. The next entry records April overhead costs.| Credit | Debit | Description | N |

|---|---|---|---|

| 2,425 | Factory Overhead | ||

| 180 645 750 850 | Prepaid Insurance Utilities Payable Cash Accumulated Depreciation—Factory Equipment | 7 | |

| To record overhead items incurred in April. |

The application of factory overhead to production is shown by arrow line 8. Factory overhead is applied to operations by tying overhead costs to other variables such as direct worker hours or machine hours utilized. Companies with process operations are increasingly likely to utilize machine hours to distribute overhead as automation increases. A single allocation basis, such as direct labor hours (or a single rate for the whole plant), does not always generate meaningful allocations. As a consequence, management might employ various rates for different areas of production. Exhibit 20.8 shows that, based on a study of its processes, GenX applies its April overhead at a rate of 120 percent of direct labor cost.

Overhead applied =Direct labor cost * Predetermined rate

$6,840 = $5,700 * 120%

GenX records its applied overhead with the following entry.

| Credit | Debit | Description | N |

|---|---|---|---|

| 6,840 | Goods in Process Inventory | ||

| 6,840 | Factory Overhead | 8 | |

| Allocated overhead costs to production at 120% of direct labor cost. |