We discussed how materials, labor, and overhead expenses are accumulated in the Goods in Process Inventory account over time, but we did not discuss the arrow lines labeled 9 and 10. These lines represent the movement of products from the manufacturing department to the completed goods inventory, and then from the finished goods inventory to the cost of goods sold. To calculate the expenses reported for these flows, first calculate the cost per unit of product and then multiply by the number of units moved.

Accounting for Goods in Process

If a process has no beginning and no ending goods in process inventory, the unit cost of goods transferred out of a process is computed as follows.

= Total cost assigned to the process (direct materials, direct labor, and overhead) /Total number of units started and finished in the periodIf a process includes a starting or ending inventory of partially processed units (or both), the total cost ascribed to the process must include all finished and incomplete units worked on throughout the period. As a result, the denominator must quantify the entire process's production activity for the time, known as equivalent units of production (or EUP), which refers to the number of units that might have been begun and finished given the cost paid during the period. This metric is then used to calculate the cost per equivalent unit and to allocate expenses to finished items and goods in process inventories.

Assume GenX adds (or introduces) 100 units into its process over a period of time. Assume that at the end of that time, the production supervisor concludes that those 100 units are 60% of the way through the process. As a result, the comparable units of output for that time period amount 60 EUP (100 units * 60 percent). This indicates that with the resources necessary to get 100 units 60% of the way through the process, GenX could have begun and finished 60 whole units.

Differences in Equivalent Units for Materials, Labor, and Overhead

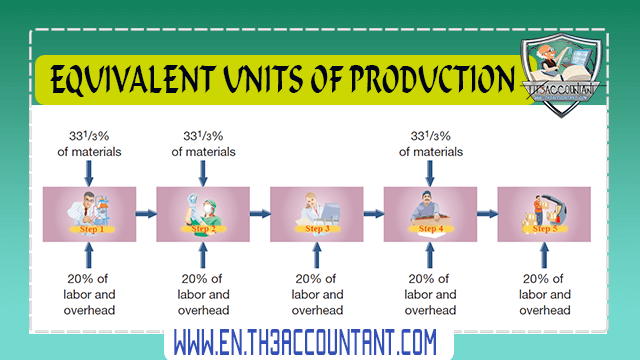

In many processes, the equivalent units of output for direct materials and direct labor and overhead are not the same. Consider a five-step process operation as an example.

This diagram illustrates how one-third of the direct material cost is increased at each of three steps: 1, 2, and 4. Each of the five phases adds one-fifth of the direct labor cost. Because overhead is applied as a percentage of direct labor for this firm, one-fifth of the overhead is also added at each phase.

When units complete step one, they are one-third complete in terms of direct materials but only one-fifth complete in terms of direct labor and overhead. When they accomplish step 2, they are two-thirds done with direct supplies but only two-fifths done with direct labor and overhead. When they accomplish step 3, they are still two-thirds complete in terms of materials but three-fifths complete in terms of labor and overhead. When they complete step 4, they are 100% complete in terms of materials (all direct materials have been added), but only four-fifths complete in terms of labor and overhead.

For instance, if 300 units of product are begun and processed via Exhibit 20.10 step 1, they are considered to be one-third complete in terms of materials. In terms of comparable completed units, the processing of these 300 units is equivalent to completing 100 EUP in terms of resources (300 units * 33,5%). However, at the end of step 1, only one-fifth of direct labor and overhead has been applied to the 300 units. This signifies that the labor and overhead equivalent units of output total 60 EUP (300 units * 20 percent).

Resources : fundamental accounting principles 20th edition (pdf) John J. Wild , Ken W. Shaw Barbara Chiappetta