The principles and processes of process costing are applied to GenX in this article. For inventory costs, the weighted-average approach is used in this figure. The FIFO approach is depicted.

PROCESS COSTING ILLUSTRATION

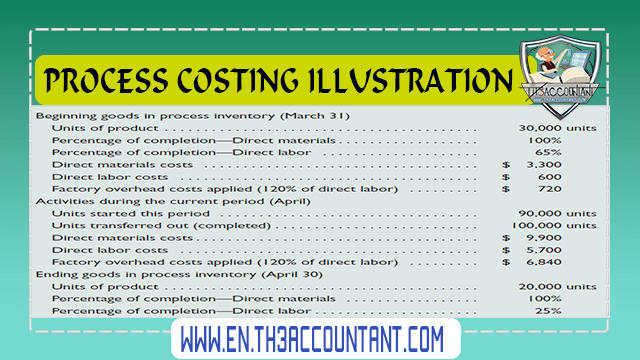

The following exhibit displays data from the production department for the month of April. Accounting for a department's activity throughout a period consists of four steps:

(1) physical flow analysis,

(2) equivalent units’ analysis,

(3) cost per equivalent unit analysis, and

(4) cost assignment and reconciliation. Each stage is described in the following sections.

Step 1: Determine the Physical Flow of Units

A physical flow reconciliation is a report that compares (1) the physical units begun during a period to (2) the physical units completed during that time. The next exhibit for April includes a physical flow reconciliation for GenX.

The weighted-average technique does not require us to differentiate the units that are just starting work from those that have already begun work. Instead, the units are regarded as part of a huge pool with an average cost per unit.

Step 2: Compute Equivalent Units of Production

The second stage is to calculate April's equivalent units of output for direct materials, direct labor, and factory overhead. As the allocation basis for GenX, overhead is imposed utilizing direct labor. This also indicates that comparable units for labor and overhead are the same. GenX used its direct materials, direct labor, and overhead to produce finished Profane units and to begin processing some unfinished units. Based on how each input was used, we must convert the physical units measured to equivalent units. Exhibit 1 shows how to calculate equivalent units by multiplying the number of physical units by the percentage of completeness for each input.

The first row of Exhibit shows units that were transported out in April. The production department finished all of the work on the 100,000 units that were transferred out. These units include 100% of the materials, labor, and overhead needed, or 100,000 equivalent units of each input (100,000 * 100%).

The second row refers to the finished items in progress, while the third, fourth, and fifth rows break it down into materials, labor, and overhead. For direct materials, the units in ending goods in process inventory (20,000 physical units) comprise all materials necessary, therefore the unfinished physical units contain 20,000 equivalent units (20,000 * 100 percent). In terms of labor, the units in the ending items in process inventory contain 25% of the labor required, implying 5,000 equivalent units of work (20,000 * 25 percent). These units are just 25% built, yet manpower is needed consistently throughout the process. For GenX, overhead is applied on the basis of direct labor, hence equivalent units for overhead are computed in the same way as labor (20,000 3 25 percent)The last row represents the total number of product units that might have been made using the inputs utilized to construct some full and some partial units. For GenX, the quantity of inputs necessary to make 100,000 complete units and start 20,000 more units is comparable to 120,000 whole units of direct materials, 105,000 whole units of direct labor, and 105,000 whole units of overhead.

Step 3: Compute the Cost per Equivalent Unit

The average cost per equivalent unit is calculated using the equivalent units of production for each product (from step 2). The weighted-average technique does not differentiate units in starting inventory from those begun this period when computing EUP; similarly, this method mixes the costs of beginning items in process inventory with the expenditures spent in the current period. Exhibit 1 depicts this technique.

The cost of direct materials averages $0.11 per EUP, calculated as the total of direct materials cost from commencing items in process inventory ($3,300) and direct materials cost spent in manufacturing.April ($9,900), which is then divided by the 120,000 EUP for materials (from 2nd step Labor and overhead expenses per equivalent unit are calculated in the same way. Specifically,

Direct labor costs, calculated as the total of labor costs in initial items, average $0.06 per EUP.

in process inventory ($600) and April labor expenses ($5,700), and this total ($6,300). divided by 105,000 EUP for labor Overhead expenses average $0.072 per EUP, calculated by adding the overhead costs in the initial items in process inventory ($720) and the overhead costs applied in April ($6,840), and dividing the total ($7,560) by 105,000 EUP for overhead.

.png)

.png)

.png)